Rubber belts are mainly divided into two categories: drive belts for power transmission and conveyor belts for material transport. They are fundamental components for achieving mechanical transmission and automated assembly line operations in industrial production.

• Cover Rubber: This comes into direct contact with the material and the rubber must be selected based on the characteristics of the material being conveyed (such as abrasiveness, sharpness, acidity, and alkalinity). Abrasion-resistant NR/SBR/BR blends are commonly used. For conveyor belts transporting food, white or light-colored rubbers (such as EPDM and silicone rubber) that meet FDA standards must be used.

• Reinforcement Material: Multi-layered nylon, polyester, or cotton canvas are typically used as the reinforcement, providing tensile strength and impact resistance. Steel cord conveyor belts are used for long-distance, high-load applications (such as in mining).

• V-Belts: These are the most widely used drive belts. Their compression layer uses high-toughness neoprene (CR) rubber due to its excellent dynamic fatigue performance, ozone resistance, and aging resistance.

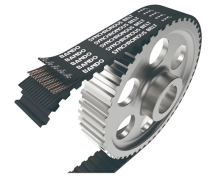

• Synchronous Belts: These combine the advantages of gears and belts, providing precise transmission. Its rubber body is typically made of hydrogenated nitrile butadiene rubber (HNBR), which possesses extremely high strength, heat resistance, and oil resistance, while the tooth surface is covered with abrasion-resistant nylon cloth.

The development trend of the conveyor belt industry is towards long service life, high efficiency, energy saving and environmental protection, and intelligent. For example, energy-saving conveyor belts reduce energy consumption by lowering the rolling resistance of the rubber; the strength of steel cord conveyor belts is continuously improving to meet the needs of larger mines. Meanwhile, in the transmission field, the demand for low-noise, high-precision synchronous belts is increasing.